- Laser Systems

- Epilog Laser Systems

- Kern Laser Systems

- Lotus Laser Systems

- Vision Engraving Systems

- ACSYS Lasertechnik

- BOFA Fume Extraction

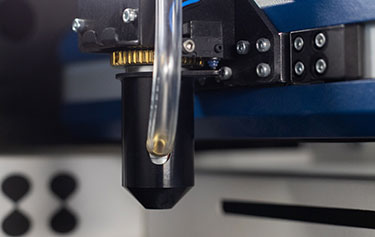

- 3D Printers

Desktop 3D Printers

Industrial 3D Printers

Metal 3D Printers

- CNC Machine tools

Haas Rotaries and Indexers

Haas Automation Systems

- Resources

- Support

- For Schools

- Rent-to-Buy